- HOME

- ABOUT US

- PRODUCTS

- REFERENCES

- DOWNLOADS

- CONTACT US

- Visuals

- 3D View

- Demo Video

ROAD BLOCKERS

BARRIERS

GSR-SX Anti-Terror Series

GateSet’s new release GSR-SX Series High Impact Rated Hydraulic Shallow Mount Road Blockers are designed to protect sensitive areas that require high level of security. The product has already proven its durability and stopping power through computer aided element analysis tests, providing compliance to IWA14-1:2013 / PAS68 / ASTM M50 standards at P1 level with N3C vehicle. With its powerful hydraulic unit, GateSet GSR-SX Series Shallow Mount Road Blockers provide reliable solutions for securing sensitive areas against ram attacks. Suitable for high frequency heavy duty operation, GSR-SX Series Road Blockers also provide easy and fast installation for projects with construction limits and time constraints.

Usage Areas

Access Control

Military Sites

Government Offices

Police Headquarters

Research Centers

Embassies

Airports

Industrial Areas

Featured Characteristics

Heavy Gauge Structure

Road Blocker Structure is made out of heavy gauge material. Underground case is 400 NPU Steel. Inside the blocking wedge there are 8 sets of 3-up hinge bars, constructed from 40x120 mm and 20x120 mm Steel Plates, which support the structure against impact.

Heavy Duty Operation

Designed for intense industrial usage with 100% Duty Cycle, by powerful HPU, strong wedge and durable hydraulic lift piston. With its 5.5 kW powerful motor GSR-SX Series are capable to complete up or down movement in 3-4 seconds without any limitation of daily usage.

Speed Control & Position Sensing

GSR-X Series possess two advanced features which extend the usage life of the system: Position Detection with weather proof proximity limit sensors which immediately stops the motor operation at limit points. Descending Speed at Closing and Opening Points which provides a silent operation.

High Impact Resistance

GSR-X Series Blockers are designed by using the cutting-edge manufacturing computer technology to meet K12 level of DOS SD-STD-02.01 standards. Computer aided element tests have proved that GSR-SX Series withstands an impact force of 7,500 kg @ 80 km/h .

Flexible and Reliable

Ease of integration with all access control equipment through its Schneider SR2 A201BD PLC unit which possesses 12 Inputs and 8 Outputs. All electronic equipment are Schneider branded with the highest reliability available in the market.

Ease of Installation

Shallow mount design allows installation within a substantially shallow pit when compared to conventional road blockers. This provides a huge advantage for projects with construction constraints.

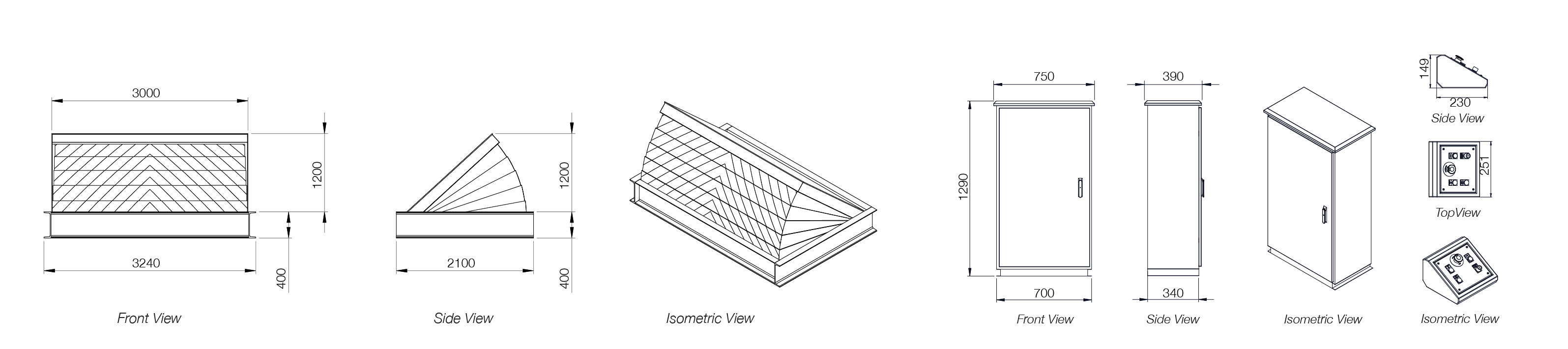

* Dimensions are given for 3000 mm Blocking Width,1200 mm Obstacle Height and Control Cabinet with Standard Configuration.

Subject to change depending on design or project needs without prior notice

Technical Specifications

BLOCKER PHYSICAL CHARACTERISTICS

| BLOCKING LENGTH | 3000 mm |

| OBSTACLE HEIGHT | 1200 mm (standard) |

| OTHER DIMENSIONS | 3242 x 2100 x 400 mm (pour GSR3120-SX) |

| BLOCKER UNDERGROUND CASE | Heavy Gauge 400 mm NPU Steel Profiles, Supported by horizontal 200 mm NPI Steel Profiles |

| BLOCKING WEDGE | Heavy Gauge 160 mm NPU Steel, Supported by Vertical 160 mm NPI Steel Profiles and 160x12 mm Steel Plates, Steel Top Plate Thickness 12 mm 8 sets of 3-up hinge bars, constructed from 40x120 mm and 20x120 mm Steel Plates |

| TREATMENT | Two Component Surface Tolerant Epoxy Mastic Coating for Corrosion Protection (Jotamastic) and Painted with Polyester Outdoor Paint, Black Finishing with Yellow Stripes on the Circular Front Steel and Top Plate |

CONTROL CABINET PHYSICAL CHARACTERISTICS

| CONTROL CABINET |

2 mm Thick Steel, Electrostatic Thermal Painting for Anti-Corrosion Resistance |

||||||||||||||||||||

| CABINET DIMENSIONS |

|

OPERATIONAL CHARACTERISTICS

| DRIVE | Heavy Duty Hydraulic |

| DRIVE POWER | Min 10 Bars / Max 120 Bars |

| RISING / FALLING TIME | 3-4 Seconds (Adjustable) |

| SPEED CONTROL | Slowing Down at Opening and Closing Limit Points |

| WORKING FREQUENCY | 300+ Cycles/Hour |

| EMERGENCY OPERATION | Rising in 1 Second (with optional EOK Kit) |

| POWER OUTAGE |

Capable to make up to 10 Complete Cycles without Electricity (with optional HPU2400 Kit) |

| POSITION DETECTION | 2 Weather Proof Proximity Limit Sensors |

| MANUAL OPERATION | Ascending and Descending with Manual Hand Pump |

ELECTRICAL CHARACTERISTICS

| ELECTRIC MOTOR | 380 V AC / 50-60 Hz. 5.5 kW, |

| CONTROL PANEL | Schneider SR2 A201BD PLC, Integration with Various Systems |

| TEST PANEL | Integrated Test Panel on Electric Cabin Cover, Phase Indicators |

RESISTANCE CHARACTERISTICS

| IMPACT RESISTANCE | 7,500 kg at 80 km/h |

| AXLE LOAD RESISTANCE | 35 Tons |

| PROTECTION CLASS | IP 65 |

| OPERATING TEMPERATURE | + 70 °C / - 15 °C |

EQUIPMENT AND ACCESSORIES

| HYDRAULIC PIPES | 18/1.5 Connector - 1/2 Radius, 350 Bars Max Pressure, 10 m Pipe Length (standard) |

| SAFETY EQUIPMENT | Emergency Stop Button (standard), Front and Rear Loop Sensor (optional) |

| STANDARD ACCESSORIES |

Remote Control Keyboard (wired), Test Unit on ECU Panel, Oil Level and Temperature Indicator, Manometer |

| OPTIONAL ACCESSORIES |

Traffic Lights, Flashing Light, Siren, Warning Sign, Drainage Pump, Touchscreen Control Keyboard |

CERTIFICATIONS AND WARRANTY

| CERTIFICATIONS | ISO 9001:2015, CE |

|

WARRANTY |

2 Years |